Protective Packaging

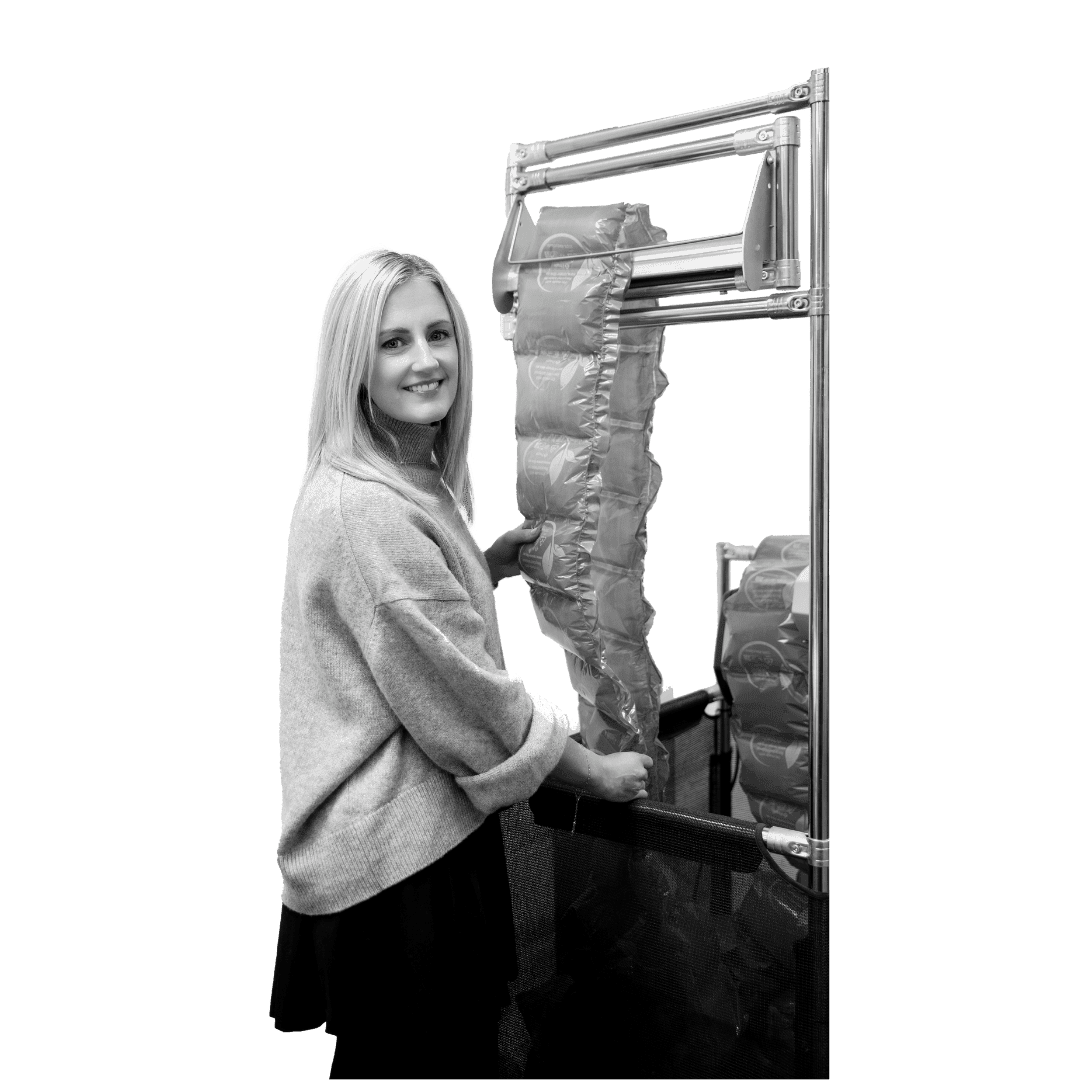

Damaged products can damage your brand. Void fill and cushioning are key to protecting products during shipping and handling. The right protective packaging keeps products safe, reduces returns, and builds customer confidence from the moment they open the box.

Protective Packaging that Delivers Confidence

Protective packaging is about more than just preventing damage—it’s about delivering a premium experience from the moment your package is opened. From void fill to edge protection, every material plays a part in safeguarding your products and reinforcing your brand’s attention to detail.

Our range includes sustainable paper void fill, air pillows, bubble wrap, foam rolls, and edge protectors—each designed to cushion, stabilise, and protect your items in transit.

Whether you’re shipping fragile glassware, electronics, or oddly shaped products, we have a protective solution to match.

No more crushed corners or noisy, half-empty boxes—just clean, secure packaging that looks as good as it performs. It’s the unsung layer of confidence that ensures every delivery arrives exactly as intended.

Hexcel wrap

Bubble wrap

Plastic corner protection

Corner edge protection

Bespoke solutions

Padded paper

Self-adhesive corrugated paper

Flexihex Protection

Airbags

Paper and air protection

VCI paper

Air cushion

We’ve got the answer.

Now what’s the question?

- How much voidfill should we be using?

- Should we use a plastic or paper solution?

- Should we be buying or renting machines?

- Is an automated solution better?

- Where should we put our machines?

- Do we need to pay plastic tax for the voidfill we use?

Got questions and need answers?

Speak to the TITAN team

Did you know?

Air-filled packaging dates back to the 1960s – Bubble wrap, one of the most popular forms of protective packaging, was originally invented in 1957 as a type of textured wallpaper. When that idea failed, it was repurposed as packaging material and officially marketed in 1960. Today, it’s valued not just for protection but also for its satisfying popping noise!

CASE STUDY

Significant reduction in damages despite a 20% reduction in void fill.

The problem

The retailer was facing a significant issue: the excessive and improper use of void fill and cushioning materials was driving up costs and contributing to a higher rate of product damage.

Our approach

After thoroughly reviewing SKU’s and order profiles, we identified the optimal box sizes and void fill solutions to minimise waste. To embed this approach, we launched a comprehensive training platform for staff. Supported by on-going refresher sessions to ensure consistent high-performance packing methods.

Result

20% reduction in void fill.

Increase in overall operational efficiency.

Significant reduction in damages.

Nature-inspired packaging is on the rise – Modern protective packaging is increasingly inspired by biomimicry—designs based on nature. For example, some packaging mimics honeycomb structures, which are incredibly strong and lightweight, offering excellent protection with minimal material use.

Did you know?

Other Products We Offer

More than just protective packaging